Mavis Tires and Brakes

Kitting Out for a Perfect Fit – NEWBERRY TANKS DELIVERS ON TIME – MAVIS TAKES ADVANTAGE OF SINGLE-SOURCING, REDUCING COSTS AND ELIMINATING DELAYS

ABOUT MAVIS TIRES & BRAKES

Since 1949, Mavis Tires & Brakes™ has been committed to providing customers premium tires and auto repair services. The company is known for value and outstanding customer service. From their original store in Mt. Vernon, New York, Mavis has grown to more than 2000+ locations in 24 states, adding oil change and auto maintenance services along the way.

THE CHALLENGE

Through recent mergers and acquisitions, Mavis was experiencing extremely rapid growth, more than doubling the number of new stores in the last year, along with a tremendous number of remodels. It was imperative that construction of these new locations stay on schedule to meet opening dates. Retrofits also needed to happen quickly and smoothly to get back to business as soon as possible.

An integral part of the new oil change locations is the oil bar where technicians can fill up their containers to pour oil back into a car when completing an oil change. Fluids are pumped through the bar from six different Roth tanks (a double-wall tank with a stainless steel outer shell and a poly inner tank). Moving away from boxed oil to this kind of more efficient oil delivery system means additional tanks (usually seven) at each location.

With multiple tanks required and all the necessary pumps, hoses, and equipment needed for each installation, Mavis was looking for a way to streamline the order, delivery, and installation process. Several manufacturers were supplying tanks and other suppliers were shipping the parts and accessories needed to install those tanks, resulting in too many moving parts.

“I have 100 different products, not just oils, and I’m shipping to multiple sites,” remarked Mavis Inventory & Logistics Manager, Steven Silva. “My main goal is to make things simple for our teams on site.”

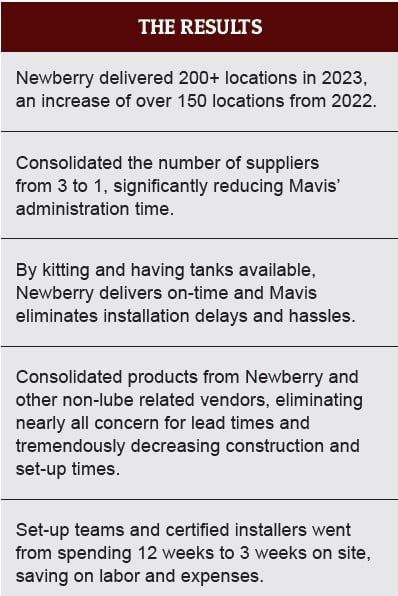

Opening 150 new locations in 2022, 350 new locations in 2023, and planning to double that in 2024, Mavis and Silva were also looking to partner with a tank manufacturer who could meet their increasing demand – for product and on-time delivery. They turned to Newberry.

THE SOLUTION

Mavis had worked with Newberry for several years, having purchased Newberry’s 250 gallon double-walled steel rectangular tank for waste oil along with certain tank equipment. When Newberry doubled its production square footprint for the manufacturing of rectangular tanks, Mavis knew they could rely on Newberry to meet their additional demand.

“Newberry has always delivered,” Silva says. “They’re the one vendor that I never have to worry about.”

Newberry had also expanded its distribution partnerships for accessories and tank-related components, while supplying Mavis with all of their Roth tanks. The addition of a strategic new sales hire knowledgeable in “kitting” – a process new to the tank industry – sealed the deal.

“It was great working with Vince (Eichhorn, Newberry sales rep) and Newberry. They made everything simple for us from the start of the project,” said Silva.

Utilizing their kitting program, Newberry packages the components necessary for

install with the tank, thus eliminating third party suppliers, simplifying distribution headaches, and even significantly reducing costs for Mavis. Now, all tanks and components arrive together at the construction site, so tank installation does not delay the overall schedule.

“We’ve got tanks and tank accessories, meaning fill caps, liquid level gauges, drop tubes, hoses, air filter regulators, pumps, oil bars, hoses, and hose reels. All those items are packaged together, how Mavis needs them, on two pallets,” explains Eichhorn. “We make it easy for Mavis to know what is on each pallet and how many go to each store. This makes it easy for the installer as well.”

The Newberry rectangular lube tanks for waste oil and that equipment come on a separate pallet with the correct size hose reels and the evacuation pump that is needed to pump the oil from their rolling waste drain pans into that rectangular waste oil tank. There’s no searching for all the equipment that goes with the different tanks during installation. It’s right there, all together on the pallet.

What is unique about what Newberry is doing is simply making it easy for the crews to take product off the pallets and go install it. All piece parts are in logical places and arrive on schedule. This single-sourcing approach also reduces costs for Mavis by saving time for the installation crew and everyone involved.

“It’s a lot more functional to make one call and place orders than calling multiple vendors and having to schedule multiple orders and deliveries for the same items,” notes Silva. “I really like the increased speed that it allows us to bring these materials to the site and then also me not having to worry about every little part and detail. Newberry is doing the picking and packing process themselves and then they’re putting it on the pallet and they’re sending it out to the site.”

With construction at 700 more sites and remodel locations anticipated this year, Mavis and Newberry are fit for the future.