RBM Company

Newberry Tanks’ Preferred Customer Program (PCP) Delivers Industry’s Shortest Lead times – RBM Capitalizes On Benefits

About RBM Company

Established in 1945, RBM Company has built a solid reputation as one of East Tennessee’s oldest and most respected providers of petroleum and equipment products and services. Dedicated to helping their clients by providing the tools needed to keep them profitable in a rapidly changing industry, RBM’s service department is second to none in ensuring total customer satisfaction.

The Challenge

With nearly 80 years in the business and a working relationship that goes back more than two decades, RBM Company and Newberry Tanks had successfully collaborated on a consignment program that allowed RBM to keep tanks in stock at their facility with no upfront costs, only to be billed when sold by RBM.

Says RBM’s Vice President of Sales Josh Maples, “We’ve always bought our smaller above ground storage tanks from Newberry, and over the last decade, we’ve also purchased the majority of our underground storage tanks from them too.”

Industry demands have shifted in recent years, however, and RBM found that this business model no longer fit their changing needs.

“In the last couple of years, there have been supply chain issues galore. Steel prices went up across the board and lead times were extending,” Maples says. “We needed to ensure we had the things our customers needed on a consistent basis.”

When Newberry introduced their new Preferred Customer Program (PCP) in 2020, RBM saw an opportunity. The biggest motivating factor was to keep inventory levels more consistent than in the past. That is what is important to RBM. A model that used detailed forecasting to plan buildouts for on-site inventory and on-demand access to tanks with the industry’s shortest lead times. Add in the perks of competitive pricing, immediate stock replenishments, and a timely response to customer needs? The decision to sign up was a no-brainer.

“We try to be problem solvers for people,” Maples says. “Especially right now, everyone knows that prices are going up and everything’s all over the place. It’s almost gotten to the point where if folks need it, they need it as soon as possible. Availability is key.”

The Solution

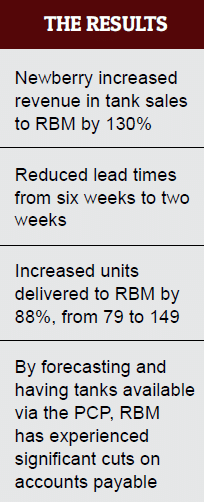

When RBM joined the Newberry PCP program 18 months ago, they did so to ensure availability of products for their customers. As it turns out, they realized a whole lot more. RBM decided to move all the tanks they kept stocked, from 300 gallons up to 2,000 gallons, to the PCP program. Newberry increased the visibility on their current and available inventory at Newberry’s location, which gave them better insight on to whom to sell and how to best fulfill orders. As a result, RBM noted a significant uptick not only in customer satisfaction but also in tank sales.

Inventory

“Simply put, when you have access to tanks and the shortest lead times in the industry, then you can sell more tanks,” Maples says. “First and foremost, this has been one of the most positive results we’ve seen. It’s helped us compete better with a lot of competitors in the local area because most of them don’t have access to this sort of program and are hampered by traditional purchasing methods, which don’t rely on yearly forecasts.”

Maples notes that in the case of their competitors, the lack of visibility on client needs can lead to lengthy lead times when the manufacturing process isn’t instigated until the order is logged. With Newberry’s PCP, RBM works directly with Newberry to forecast yearly requirements and then those requirements are automatically put into the production pipeline so if any changes arise, minor adjustments can be made rather than larger, more costly ones.

The impact on lead times has been substantial, decreasing by 67% from six weeks to two. Being able to completely fill trucks with tank shipments rather than shipping piecemeal has also led to notable savings in transportation/fuel costs as well as a reduction in air pollution.

“The positive benefits of the PCP program trickle down all the way to the end user in a multitude of ways. It might be hard to put a calculation on that comprehensively, but it’s significant,” Maples says.

Speed

In one such example, Maples details a situation only a few months ago when one of RBM’s customers, a farmer, developed a leak in his existing fuel tank. Typically, an order would have been generated for a new tank and production would have commenced at that point. However, with Newberry’s PCP program, RBM had adequate amounts of tanks available and was able to get the farmer his new tank in a very short time, correcting the issue quickly and avoiding any delays in operations.

“If he would’ve gone to a competitor who was with another tank manufacturer, they would’ve had to submit an order right then and it would’ve taken six weeks or longer before they were able to help him,” Maples says. “Because of the PCP program, we had availability and were able to get it out in a couple of days.”

Proactive Approach

It’s this sort of proactive approach putting smiles on the faces of RBM’s customers. It’s this partnership between RBM and Newberry with the Preferred Customer Program that continues to slash lead times, increase demand from present customers, and generate new business. “RBM and Newberry have been members of the Petroleum Equipment Institute (PEI) since the beginning of that organization, and over the years, we’ve grown together and developed those close personal relationships. You can look at the numbers and dollars and cents of business as much as you want, but I’m a firm believer that it all goes back to relationships in the end.”

We’ve always bought our smaller above ground storage tanks from Newberry, and over the last decade, we’ve also purchased the majority of our underground storage tanks from them too.”

Josh Maples VP of Sales